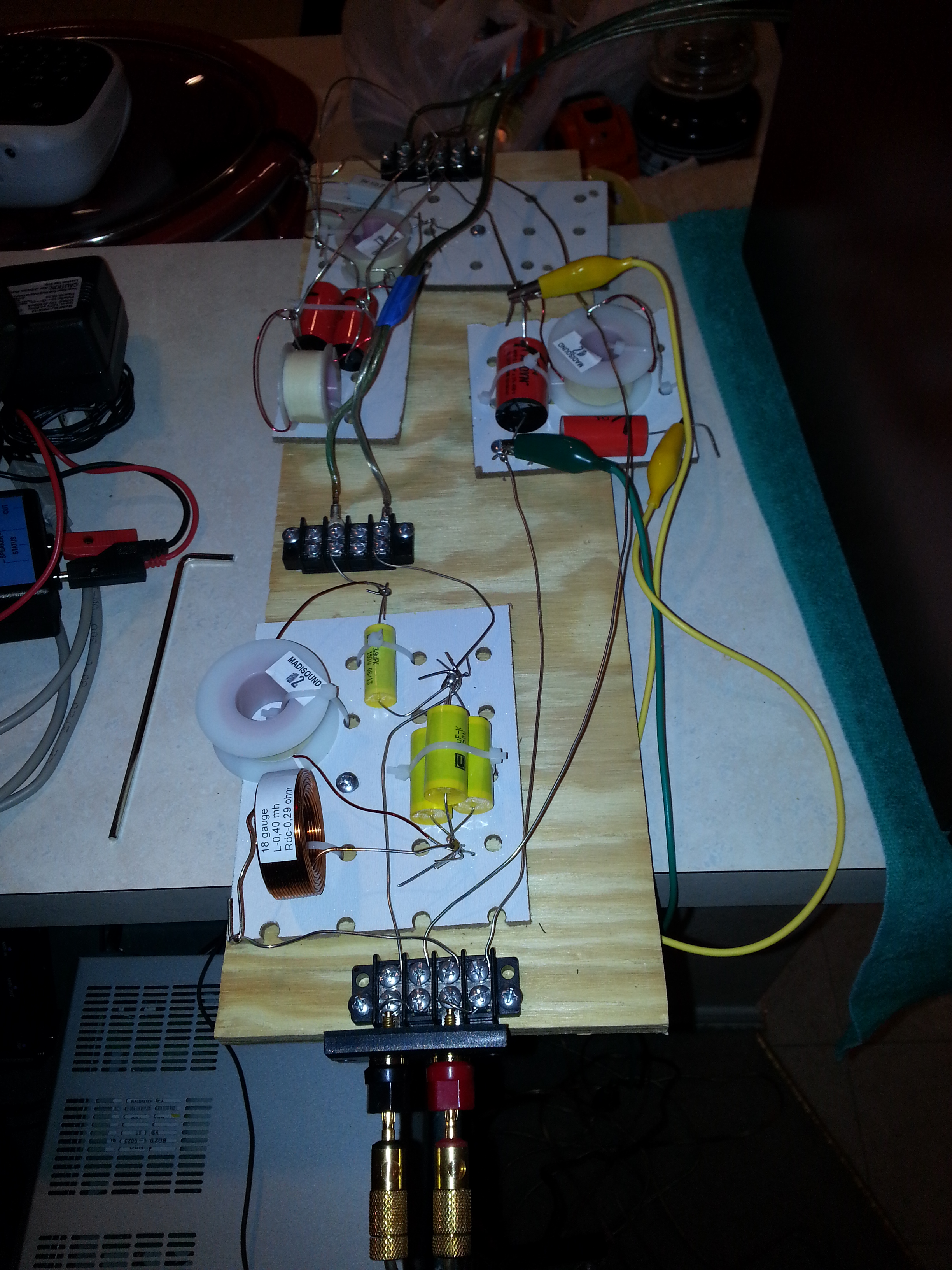

Driver’s mounted – check. Cabinet port cut – check. Cross-over – parts on order.

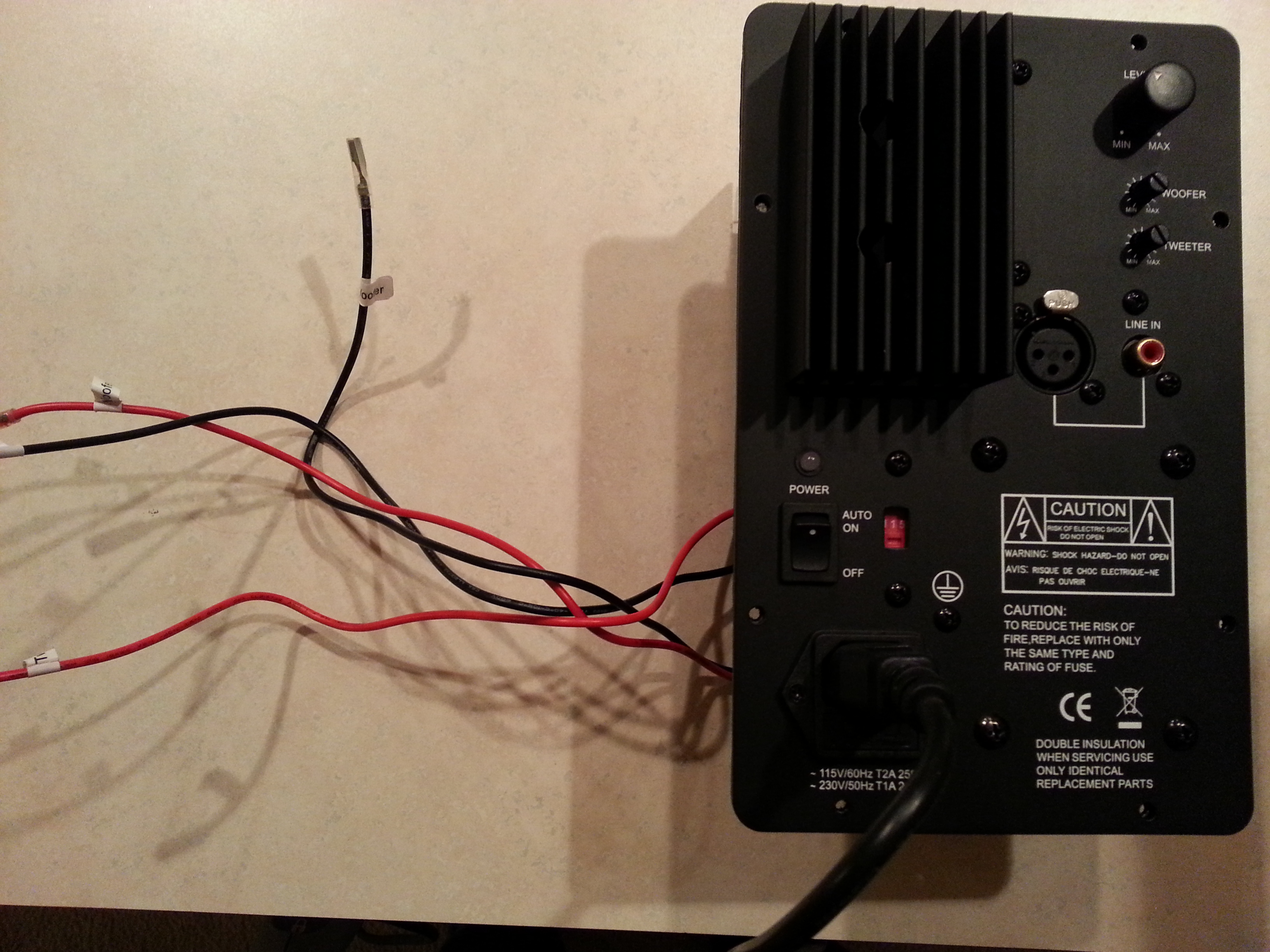

So I drug out some Dayton Audio bi-amplifiers. What is a bi-amplifier? Two amplifiers, one each for the tweeter and woofer, along with an electronic cross-over circuit.

These were the second series Dayton Audio produced. The high- and low-pass sections have separately adjustable cross-over points. Frequencies are limited to 2.2 kHz, 3.2 kHz, 3.8 kHz, 4.2 kHz, and 5 kHz. Order is 4th Linkwitz-Riley. (In the first series, the cross-over was fixed to 3.0 kHz.) The electronic crossover also has a +4 dB bass lift circuit. Presumably the bass-lift is for bass extension. Looking at the lift cut-out frequency, the circuit actually has the appearance of a diffraction compensation.

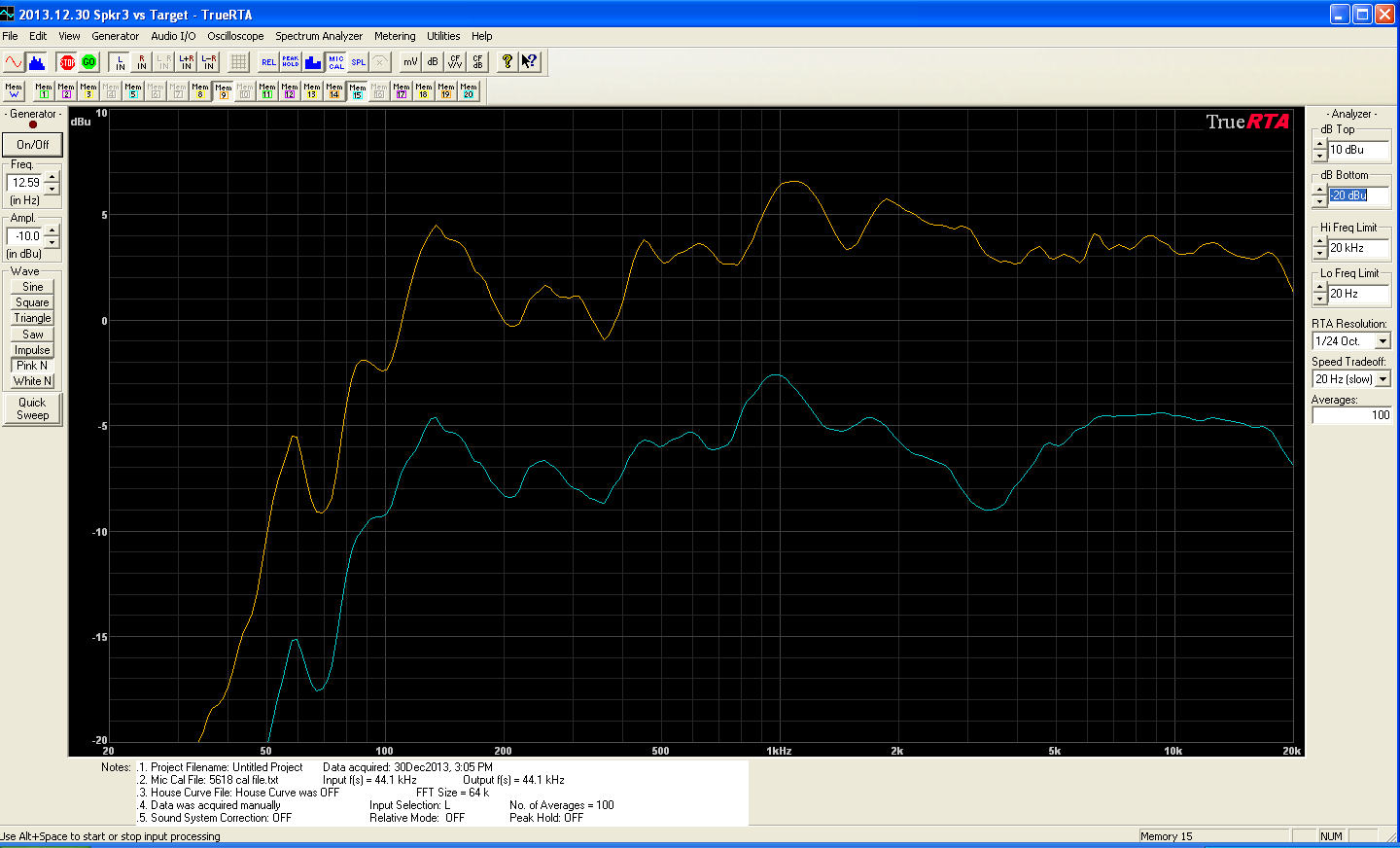

Results – sounded OK with the lift compensation enabled. Woofers are crossed over at 2.2 kHz, the tweeter at 3.2 kHz. Just sounded a little bright, maybe 3 dB to hot on the tweeters.